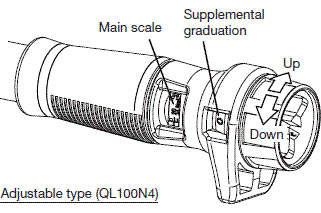

Adjustable

Features an external scale that can be easily changed by moving knob or twisting body to set a particular torque value.

- The torque setting can be easily viewed and changed by turning end knob to move the scales.

- Because of its easy torque setting style, it can be susceptible to unauthorized or inadvertent changes to the torque setting.

- Ideal for applications that require a variety of torque settings using one tool.

For Torque Wrenches

Turn end knob CW to increase torque setting and CCW to decrease; lock in place with wing nut locker. Easily view torque setting on scales.

Examples of Adjustable Models: QL, CL, DQL, MTQL, QLLS, MQL

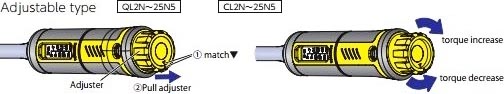

Match the marks and keep the adjuster pulling. Twist adjuster. The adjuster will return to the original position after releasing it. The adjuster will slip without pulling.

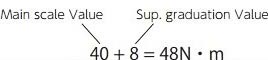

How to read scale

Add the value shown on the main scale and the value shown on the sup. graduation. (only for the torque wrench with main and sup. Graduation)

The above example indicates 48N • m because its main scale shows 40 and sup. graduation shows 8.

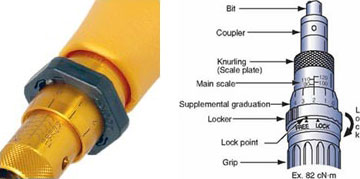

For Torque Screwdrivers

Move black lock ring to unlock position and while holding main knurled part, twist body to change torque setting.

Examples of Adjustable Models: RTD, LTD, AMRD, BMRD, AMLD, BMLD

Preset

Features no scale on the body of the tool.

- Because there are no scales, a torque tester and a specialized adjusting or thrust ring tool are required to set the torque value.

- Ideal for mass assembly applications where one torque setting is dedicated to one tool.

- Since this type requires additional equipment to change the torque, it prevents the torque setting from being changed by unauthorized personnel.

- Preset styles have lower maintenance costs compared to other types of torque tools due primarily to the fact that there is no scale to maintain and calibrate.

For Torque Wrenches

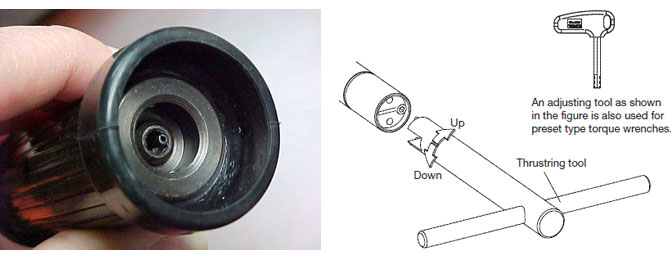

Requires torque setting tool and torque tester to change torque value.

Tools that require a thrust ring tool have an end cap that must be removed and a thrust ring screw that is loosened, then the thrust ring tool is used to fit into two holes to move CW or CCW to increase or decrease torque value. For tools that take adjusting keys, the key fits directly into the end of the tool. The wrench is checked against a torque tester to verify torque value. Adjustments are made until the required setting consistently shows on the torque tester.

Examples of Preset Models: SP, RSP, QSP, CSP, QSPCA, MQSP

For Torque Screwdrivers

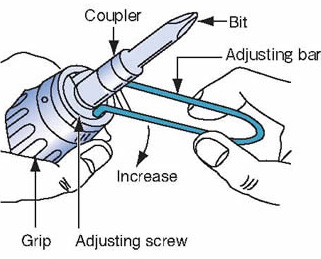

Requires torque setting bar and torque driver tester to change torque value.

While holding the driver, insert adjusting tool bar into the grooves at the base of the handle. Turn CW to increase torque and CCW to decrease. Confirm value by checking on torque driver tester. Adjust and recheck until target torque is consistently achieved.

RNTD120CN

RNTD60CN

Pre-lock

Features main and supplemental scales, but no adjustment knob.

- The torque setting can be easily viewed and changed but requires a standard hex key to move the scale to the required torque setting.

- This type combines the advantages of the adjustable and preset types, by easily setting the torque value without a torque tester yet keeping it secured by requiring a key for setting the scale.

- Ideal for applications that require quick visual confirmation of the torque setting, variety of torque settings on one tool, and the added security to prevent inadvertent setting changes.

Use a standard hex key to move the scale to desired torque setting.

Examples of Pre-lock models: PQL, PCL, MPQL, PQLLS

Dial Indicating

Features scale, main pointer, and memory pointer.

- Primarily used for measuring these types of tools, may also be used for tightening. Review the following instructions on how to make the tightening processes quick and easy using the scale position and memory pointer or preloader.

For Torque Wrenches

Dial Indication types

DB, CDB, T

- For measurement

The scale on the dial gauge can be rotated. Press the dial case from above and tum t.he pointer to correctly match “0”. - Presetting exclusively for tightening

Alternatively, the desired torque can be preset on the dial beforehand, and then the bolt can be tightened until the pointer shows “0”.

For Torque Screwdrivers

FTDS0-400CN

Method of preloading the FTD

The preload function is a function that uses the handle to apply a preloading torque close to that of the measuring point to minimize the twisting angle during measurement.

In the FTD torque screwdrivers. a preload function is provided to prevent your wrist from becoming strained and the torque scale from becoming difficult to read when operating close to the maximum torque.

- Holding the FTD Screwdriver with your left hand and turn the preload handle in the counterclockwise direction using the fingers of your right hand (in case of clockwise measuring).

- After some sUpping turns. the needle will begin to move. and it will be easy to set an optional torque value.

- If you do not wish to use the preload function. turn the preload handle until there is no tension and the central set indicator (red mark) points to the FREE mark.

FTD-S

Method of setting the FTD-S indicator and memory pointer

- Make sure the indicator is pointing to zero by matching the scale. If not. adjust to zero by lightly pushing down on the scale and rotating it.

- Turn the memory pointer in the direction opposite to the measuring direction until it matches the main indicator.

- Carry out torque measurement or torque tightening.